Extend Tool Life. Reduce Downtime. Proven Performance.

Advanced surface treatments that increase tool longevity, resist wear, corrosion, and improve part quality across various industries.

Proudly supporting some of the most innovative manufacturers in the US and the Globe

Are Tool Failures Disrupting Your Production?

Every minute of unplanned downtime is costly. Tools that wear out too soon can lead to misformed parts, excess scrap, increased labor, and costly production delays. Many companies rely on outdated technology that flakes, wears unevenly, or requires frequent rework. If your tooling isn’t meeting your performance demands—or is limiting your output—it’s time for a better solution.

At Dynamic, we provide advanced wear-resistant surface treatments that dramatically increase tool longevity, protect against wear and corrosion, and help manufacturers produce higher-quality parts more efficiently. Our proven technologies are trusted across injection molding, die casting, automotive, aerospace, and other demanding industries.

We make a difference on the production floor!

Introducing Dynamic’s Advanced Surface Treatments

Up to 10x increase in tool life

Reduced wear, corrosion and thermal fatigue as well as increased lubricity.

Consistent results—even on intricate geometries

Environmentally friendly, EPA-compliant processes with zero hazardous waste

Up to 10x tool life

Reduced wear, soldering, and thermal fatigue

Consistent results—even on intricate geometries

Environmentally friendly, EPA-compliant processes with zero hazardous waste

Our proprietary processes are engineered to solve real-world wear challenges that traditional nitriding and coatings can’t. Whether you’re dealing with abrasive materials, corrosive environments, or the need to reduce tool cost. Dynamic has a solution tailored to your needs.

Our offerings include:

-

DYNA-BLUE®: A low temperature, diffusion-based surface treatment that provides high hardness (75+), increased wear & corrosion resistance, lubricity, and an oxide layer that retains lube and anti-galling properties.

- DYNA-BRITE: Same benefits as DYNA-BLUE with no oxide layer to provide better release, helping to maintain gloss levels and high finishes, particularly for plastics.

- DYNA-COAT: a family of hard coatings (90+ HRC equivalent) for ferrous and non-ferrous materials such as Berryleum Copper. Coatings such as TiN, CrN, CrWN and TiAIN are typical.

-

DYNA-BLUE PLUS™: Adds enhanced surface finish and longevity for complex or refurbished tools.

-

DYNA-MAX™: A duplex process that combines DYNA-BLUE® with PVD coatings for maximum hardness and wear resistance.

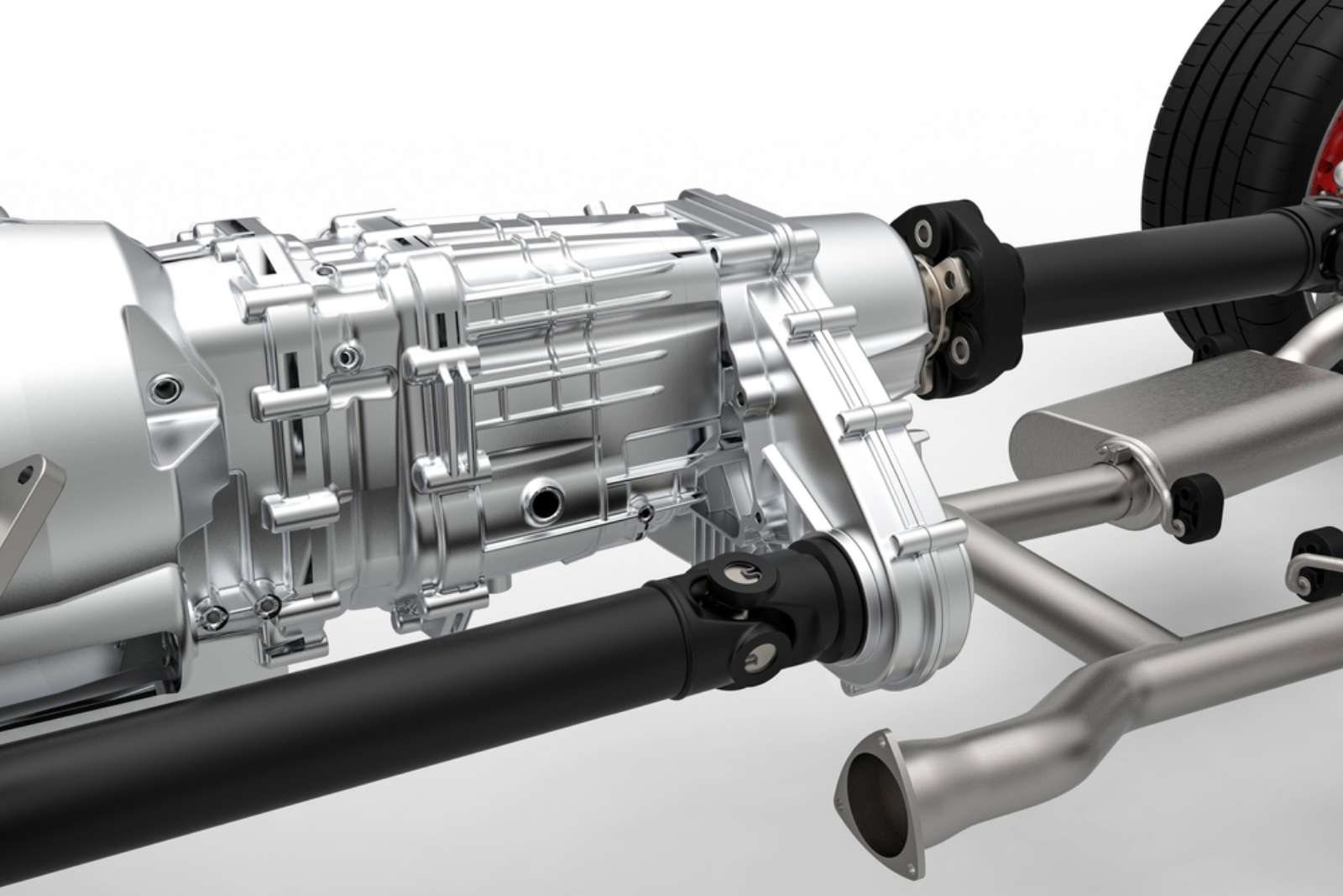

Trusted Across Diverse Industries

DynaBlue treatments are trusted by engineers and manufacturers in some of the most demanding sectors, including:

Injection & Compression (SMC) Molding

Glass-reinforced plastics, carbon fiber, and abrasive polymers can dramatically reduce tool life. Get DYNA-BLUE and DYNA-BRITE to dramatically extend tool life.

Die Casting

MAXIMIZE TOOL LIFE: Protect against wear, soldering, erosion, heat-checking, and corrosion – even in aluminum or magnesium structural casings.

Forging & Hot Forming

Increase Tool Life – prevent wear, erosion, cracking, softening, thermal fatigue, and heat checking. Less downtime – increased production.

Aerospace & Military

DYNA-BLUE can even be applied to stainless steels and high-nickel alloys such as Inconel. DYNA-BLUE also meets AMS 2757 and other military specs.

Simple and Efficient Treatment Process

Working with Dynamic is straightforward. We’ve streamlined the entire process to deliver exceptional results with minimal disruption:

Consultation

We listen to your specific tooling challenges and performance goals.

Data Collection

We inspect the steel type, current failure modes, and customer requirements.

Process Design & Application

We apply the optimal DYNA-BLUE® process, tailored to your material, objectives, and application.

Quality Assurance

Every part is tested and inspected to ensure performance specs are met or exceeded.

Proven Results with Leading Manufacturers

Incredible teams we get to work with.

“Ran mold using polypropylene with 30% glass, after 2,000,000 plus cycles, parting lines were still sharp. We saved Ford over $360,000.00”

Injection Mold Customer

“The DYNA-BLUE process has been a pleasant surprise in our long-time battle with erosion and soldering. The crankcase tool you applied this process to ran very successfully, and we were running a low .3% iron, which makes this even more remarkable.”

Die-Cast Customer

“Dynamic’s ability to turn our production tooling around quickly and predictably has been a great help to our production needs. Plus, DYNA-BLUE on our press tooling has greatly improved die life.”

Forging Customer

The Hidden Costs of Tool Wear — and How to Prevent Them.

Discover the seven most common tooling challenges that lead to downtime, scrap, and lost production — and how the DynaBlue Process helps manufacturers extend tool life up to 5×.

This free guide gives you practical, engineering-based insight into how wear-resistant coatings solve everyday problems like abrasion, corrosion, and thermal fatigue — without changing your current process.

Download your free copy today and start protecting your tools — and your bottom line.